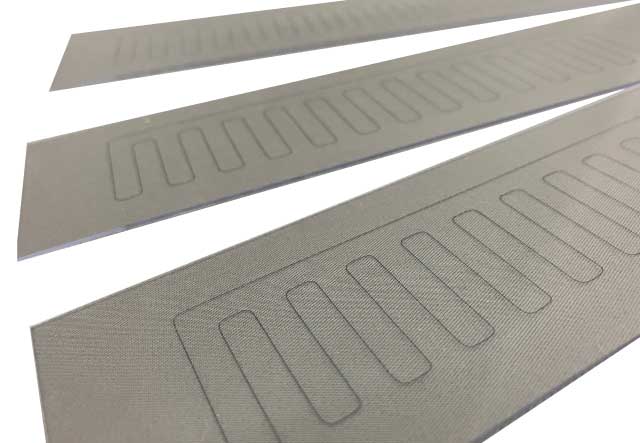

Film heater

A wiring pattern formed on the film works as a heater by passing electric current.

Features

It works as a film heater by passing current through wiring patterns created by lamination technology and ultrasound-based fine wiring technology.

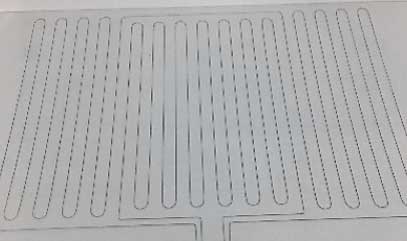

Wiring pattern technology

Since wiring patterns with high degree of freedom can be constructed, optimal wiring patterns are applied to parts requiring high light transmittance to achieve anti-fogging and deicing functions.

(No pattern mask or printing plate is required, and wiring can be designed based on CAD data.)

Environmental

Compared with a planar heater that uses etching, etc., it uses a metal wire with a constant wire diameter, so it has features such as less fluctuation in characteristic impedance and less waste liquid and waste material, making it environmentally friendly.

Available conductors

The wire diameter can be selected from 0.05 to 0.12mm, and can be selected according to the purpose.

Copper, Nichrome (NiCr), Kanthal (FeCrAl), Tungsten, etc. are available as the wire.

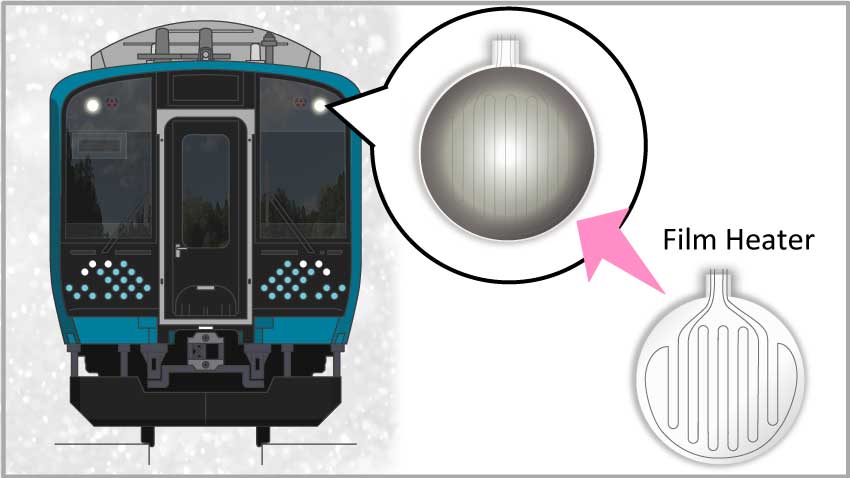

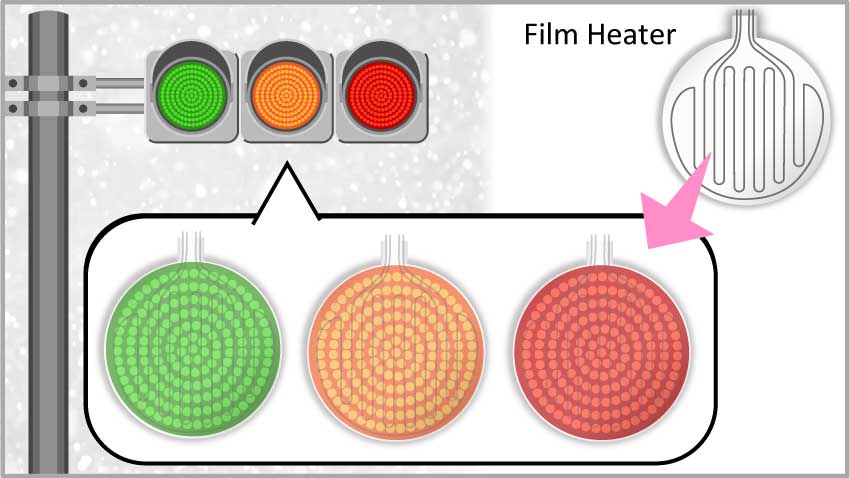

Applications

Millimeter-wave radars, LiDAR, cameras, lamps, etc.

It is effective for snow-melting and ice-melting functions, prevention of fogging, keeping warm, etc. to parts requiring high light transmittance.

Headlamp

Traffic lights, signs, signboards, and other lamps

Specifications

Item |

Characteristics |

|---|---|

Pattern shape |

A variety of patternable |

Pattern size |

Max 350×280㎜ |

Pattern spacing |

Min 0.3mm |

Base material type and thickness |

PC (polycarbonate) |

Wiring material |

Copper, Nichrome (NiCr), Kanthal (FeCrAl), Tungsten, etc. |

Wiring diameter |

Φ0.05mm-0.12mm |

Applications |

Snow melting, de-icing, defogging, keeping warm, attachment to heating targets, etc. |

Click here for a table regarding the power consumption of film heaters.

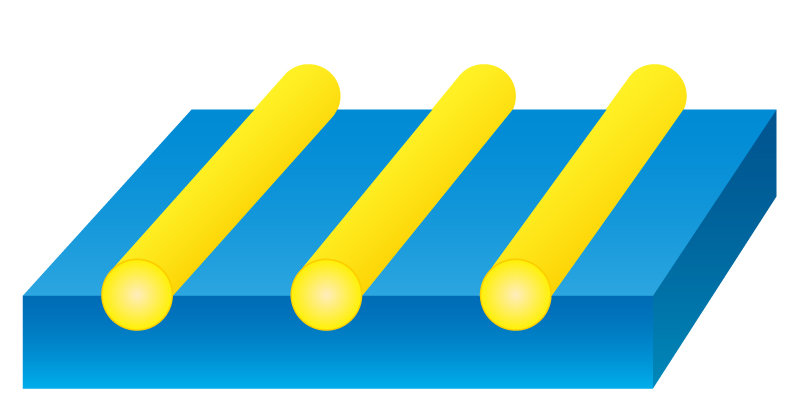

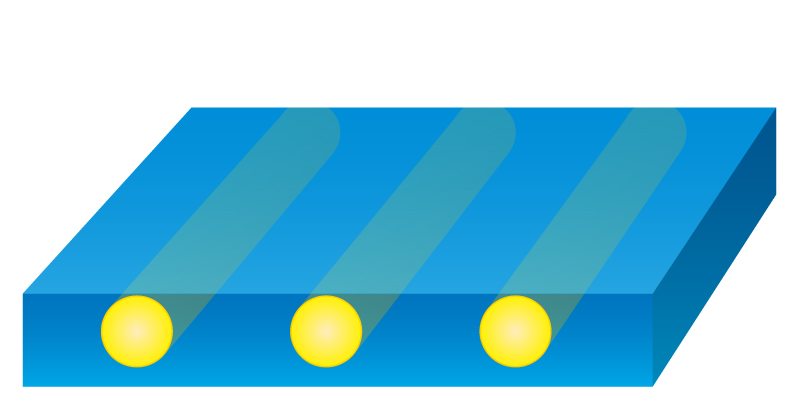

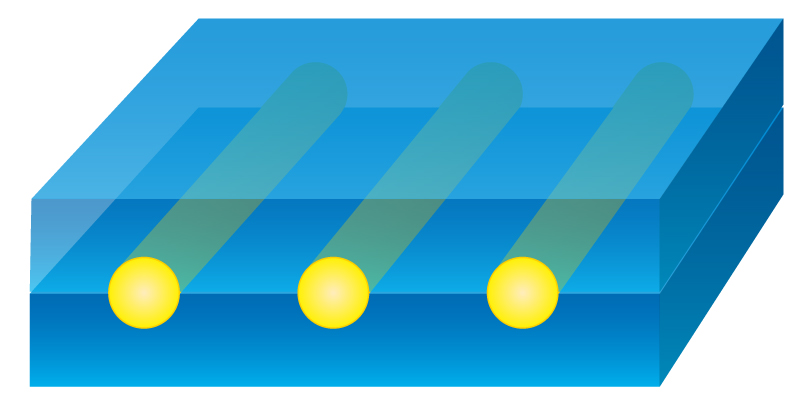

Configuration of the film heater

Condition of only embedding wires in the base material

Embedding and planarizing wires in the substrate by press treatment

Laminate with the same base material

If you are interested in film heaters, please also see this article!

We accept manufacturing outsourcing

Wiring patterns can also be formed by screen printing. Please feel free to inquire.