What is a Film Heater?

By using our lamination technology and wiring patterns constructed with fine wiring technology, we can achieve anti-fogging and anti-icing functions by providing optimal wiring patterns for parts that require high light transmittance.

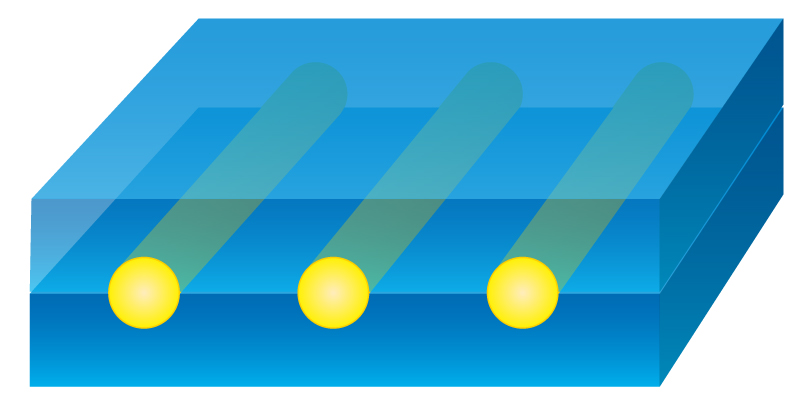

Principle and Structure of Film Heater

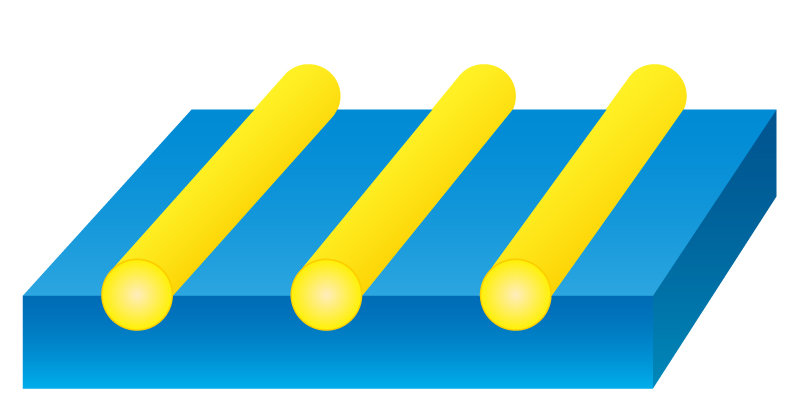

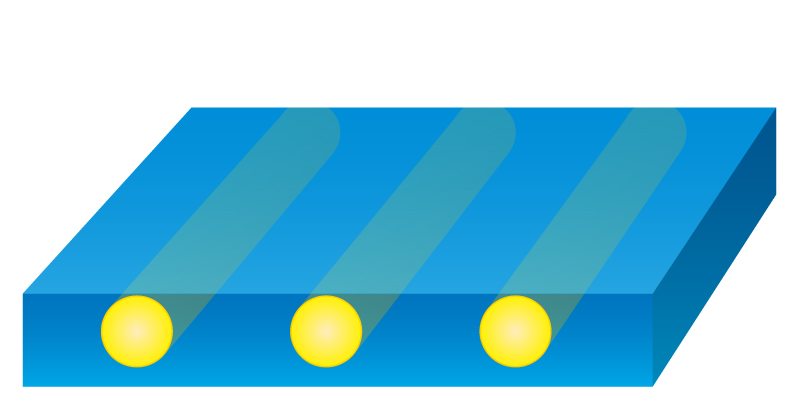

When electricity flows through conductive wires such as copper or nichrome wires, heat is generated due to electrical resistance. A film heater places conductive wires on a plastic film and heats the film itself by passing electricity through it. Our film heater has three types of configurations, allowing you to choose the one that suits your needs.

Embedding wires into the base material only.

Embedding and flattening wires into the base material through a pressing process.

Laminating with the same base material.

Specifications:

Item: |

Characteristics: |

|---|---|

Pattern shape: |

Various pattern formations possible. |

Pattern size: |

Max 350 x 280mm |

Pattern spacing: |

Min 0.3mm |

Base material and thickness: |

PC (Polycarbonate) PETG (Glycol-Modified Polyethylene Terephthalate), etc. Can be used for both double-sided laminate type and single-layer type Base thickness: 75um~ (depending on the base material) |

Item: |

Characteristics: |

|---|---|

Wiring material: |

Copper, nichrome (NiCr), kanthal (FeCrAl), tungsten, etc. |

Wire diameter: |

Φ0.05mm - 0.12mm |

Applications: |

Snow melting, de-icing, defogging, keeping warm, attachment to heating targets, etc. |

How to Use and Utilize Film Heater

Film heaters are commonly used in industries such as automotive, railway, construction, and medical fields. Our film heater allows wiring forming according to the customer's application, so if you have any of the above concerns, please feel free to contact us, regardless of the industry. We also accept manufacturing outsourcing inquiries.

Automotive

Sensors for autonomous driving, etc.

LED Lights

LED Lights: Heaters for snow melting

Heating stages

Heating stages for microscopes and other devices

Housing equipment and infrastructure

Fog prevention for washbasins

Heaters for surveillance cameras

Heaters for traffic lights and signs

Features of Film Heater

By utilizing low-resistance metal wires, it is possible to act as a heater even at low voltages.

Since a metal wire with a constant wire diameter is used, the resistance fluctuation is small and the temperature unevenness is also small.

As it is a wire pattern heater, not a surface heater, it allows electromagnetic waves to pass through.

Compared with etching, it is more environmentally friendly with fewer waste fluids and waste materials.

By changing the CAD data, the wiring pattern can be modified easily.

Since it does not require plates, it can be cost-effective even for small-lot, multi-product manufacturing. The initial cost is also lower.

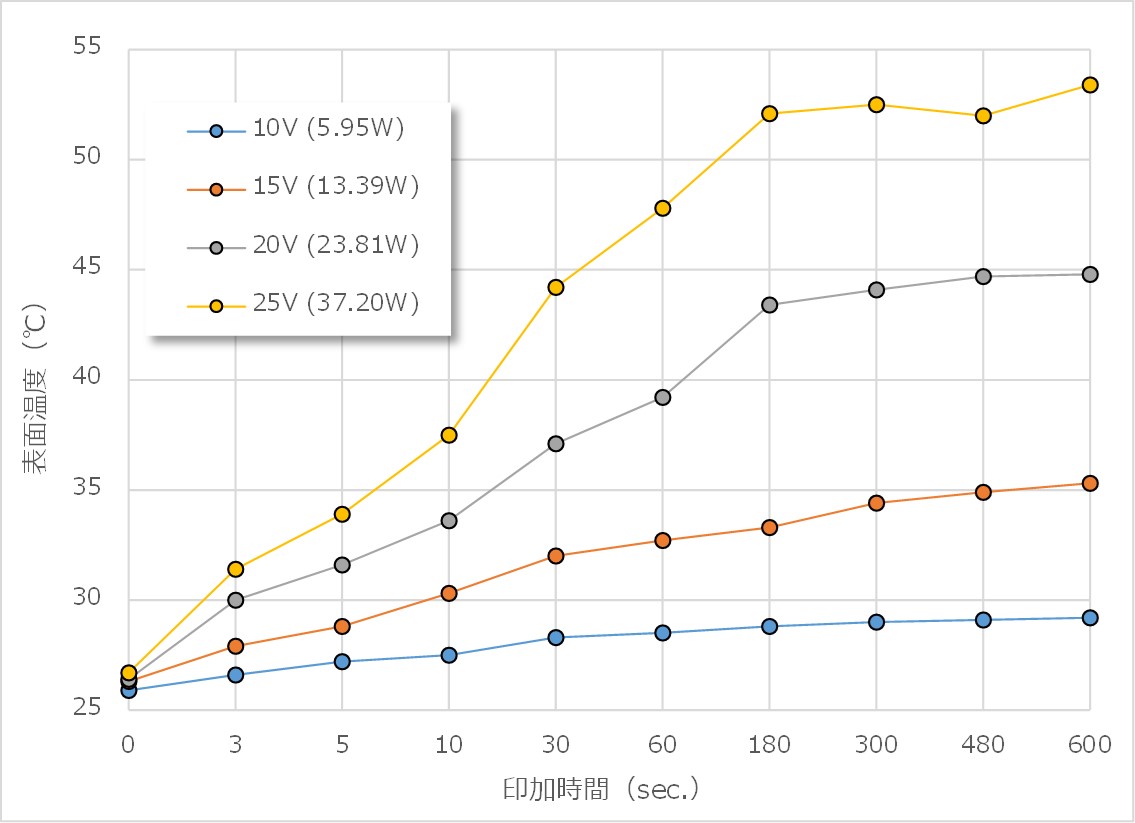

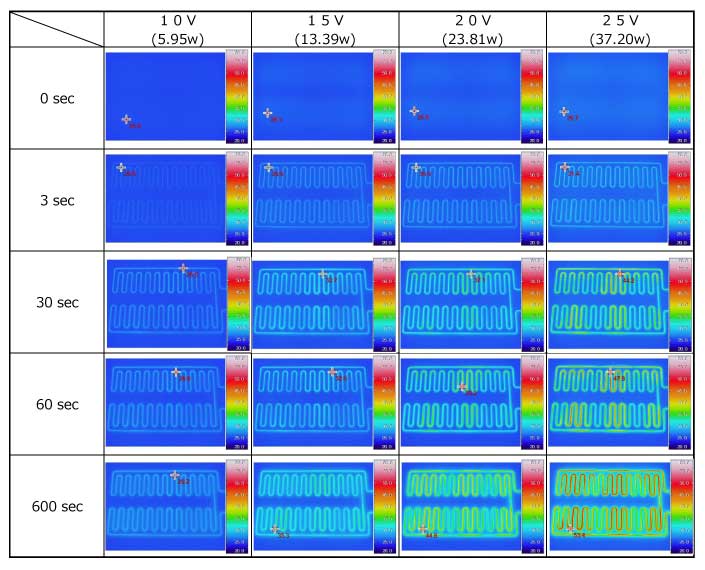

Temperature Characteristics of Film Heater

Substrate: PET-G

Sheet Size:600×400mm

Heater Pattern: Formed uniformly across the entire surface with a 20mm spacing

Heater Wire: Coated copper wire Φ100µm (16.8Ω)

Applied Voltage (V): 10 (5.95), 15 (13.39), 20 (23.81), 25 (37.20)

(Values in parentheses indicate power consumption in watts)

Differences from other methods

There are various manufacturing methods for film heaters. We will explain the differences between film heaters manufactured using other methods and our company's film heater.

Film heaters manufactured using other methods: |

Our film heater: |

|---|---|

[Heater Wire Formation through Etching] ✖ Etching is not environmentally friendly because of the large amount of etching waste fluids and waste materials. |

〇 Simply arranging common wires such as copper or nichrome on the film, making it environmentally friendly. |

[Heater Wire Formation through Printing]

✖ Printing accuracy directly affects heater accuracy, leading to significant variations. ✖ When using materials like silver ink, it becomes expensive. |

〇 Unlike etching or printing, the conductive parts are wires, making them less prone to breakage, ensuring stable resistance values, and providing physical strength. |

[Panel heater using transparent conductive Layer]

✖ Transparent conductive materials such as ITO are very expensive. |

〇 When copper or nichrome is used as the wiring material, it is inexpensive. |

We are looking for applications for film heaters.

If you are interested in film heaters, please take a look at these articles: