CMP slurry (Chemical Mechanical Polishing slurry)

We can provide CMP slurry that meets your needs.

Slurry Tanks

Features

CMP slurry product lineup

- [For wiring formation]CMP slurry for semiconductor (Cu CMP)

- [For wiring formation]CMP slurry for semiconductor (Ta CMP)

- [For wiring formation]CMP slurry for semiconductor (W CMP)

- [For TSV]CMP slurry for semiconductor (Thick film Cu CMP)

- [For TSV]CMP slurry for semiconductor (Si CMP)

- [For Resin Polishing]CMP slurry for package (PI Polishing CMP)

- [For resin polishing]CMP slurry for packaging (Filler-filled resin-film CMP)

- [Others]CMP slurry for semiconductor (Oxide film CMP)

- [Others]Slurry for HDD (Magnetic Head Polishing)

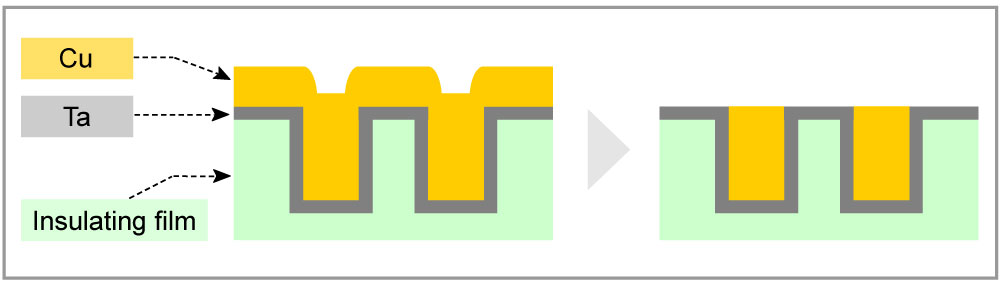

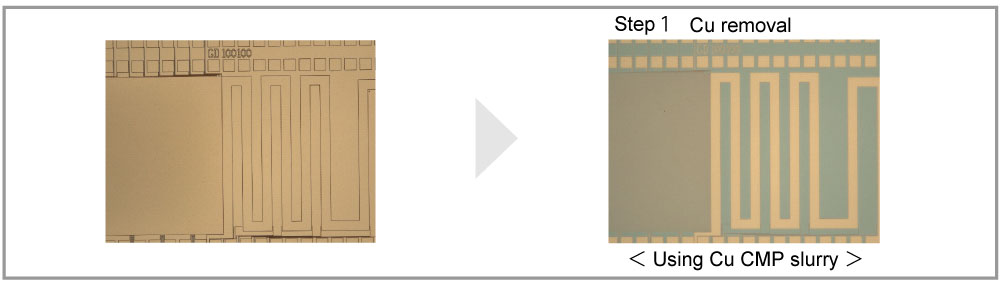

[For wiring formation]CMP slurry for semiconductor (Cu CMP)

Polishing characteristics (Product name: TPC)

Cu is polished with Cu CMP slurry.

Polishing is stopped on Ta.

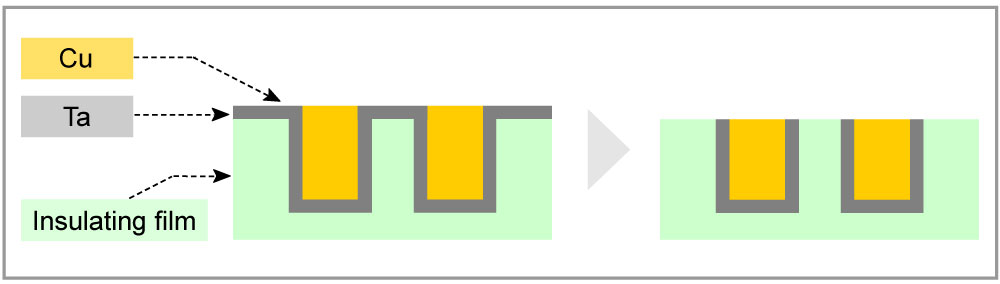

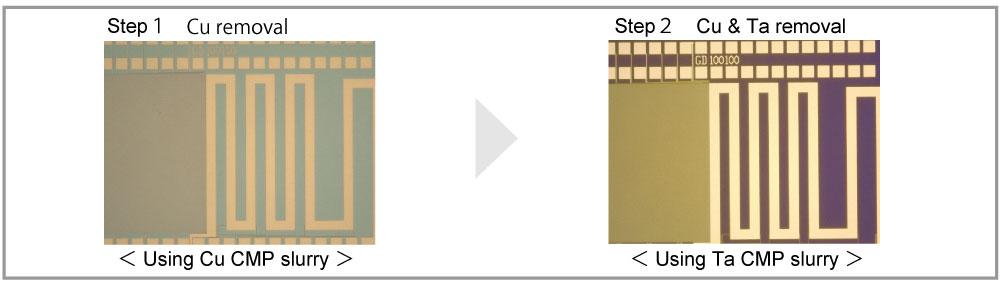

[For wiring formation]CMP slurry for semiconductor (Ta CMP)

Polishing characteristics (Product name: MKT)

・ Oxidant H2O2 based

・ Cu removal rate adjustable

・ High dispersion stability (over 1 year)

Ta and Cu are polished with Ta CMP slurry.

Ta is polished, exposing the insulating film and Cu.

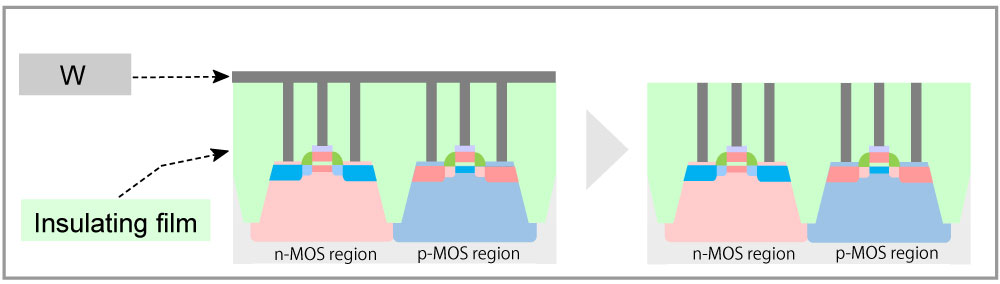

[For wiring formation]CMP slurry for semiconductor (W CMP)

Polishing characteristics (Product name: MKW)

W is polished with W CMP slurry.

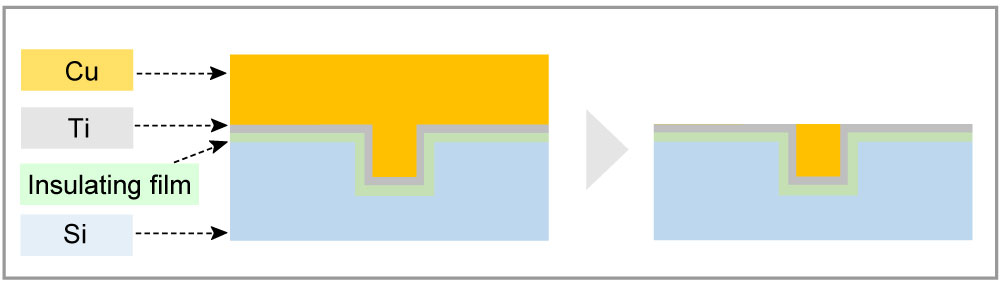

[For TSV]CMP slurry for semiconductor (Thick film Cu CMP)

Polishing characteristics (Product name: SE-High)

・ Oxidant H2O2 based

・ Cu high-speed removal on the order of microns

・ High dispersion stability (over 1 year)

Cu is polished with thick film Cu CMP slurry.

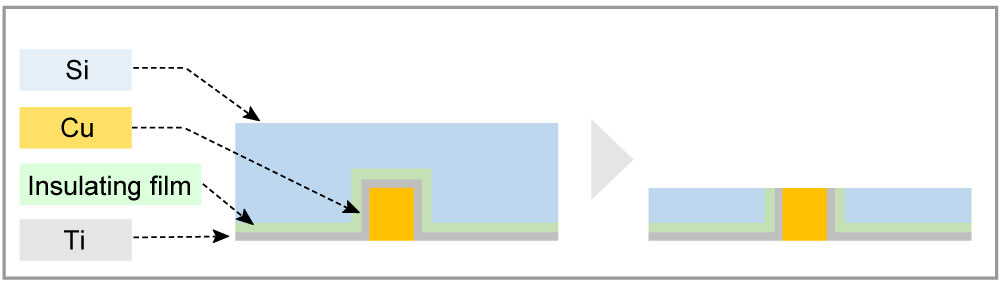

[For TSV]CMP slurry for semiconductor (Si CMP)

Polishing characteristics (Product name: Si-07)

Si, insulation film, and Ti are polished with Si CMP slurry.

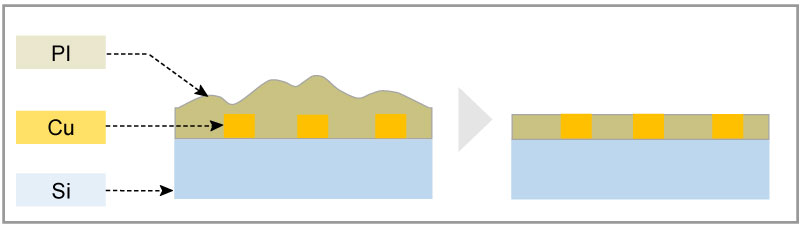

[For Resin Polishing]CMP slurry for package (PI Polishing CMP)

Polishing characteristics (Product name: PI-01)

・ Polyimide high-speed removal on the order of microns

・ Achieves low surface roughness after polishing

・ Simultaneous polishing with copper wiring possible

PI is polished with PI polishing CMP slurry.

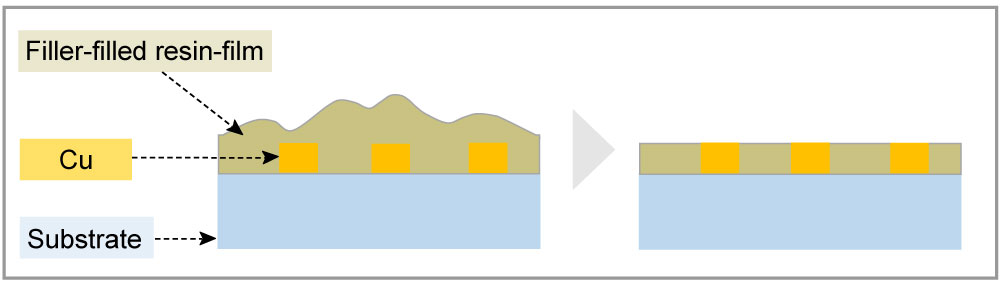

[For resin polishing]CMP slurry for packaging (Filler-filled resin-film CMP)

Polishing characteristics (Product name: CME-01)

・ High-speed removal of filler-containing resin film

・ Simultaneous polishing with copper wiring possible

※Dilution possible as needed.

Filler-filled resin-film is polished with the CMP slurry.

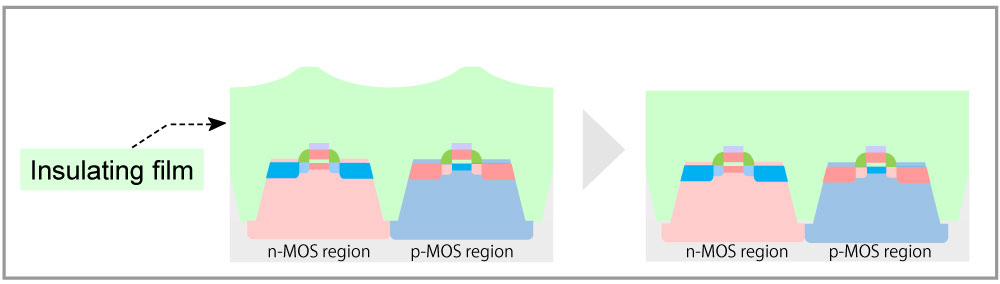

[Others]CMP slurry for semiconductor (Oxide film CMP)

Polishing characteristics (Product name: CMS)

・ Excellent removal rate for oxide films

・ Concentrated type available (10 times concentration)

・ Good redispersion

・ Achieves good surface roughness and cleanliness after polishing

Insulating film is polished with oxide film CMP slurry.

[Others]Slurry for HDD (Magnetic Head Polishing)

Polishing characteristics (Product name: DS-01)

・ Oil-based diamond slurry

・ Good redispersion, achieves high-speed polishing with low scratching

・ Reduction of adherends to the polished object after polishing

・ Oil-based + anti-oxidation agent achieves high corrosion prevention effect

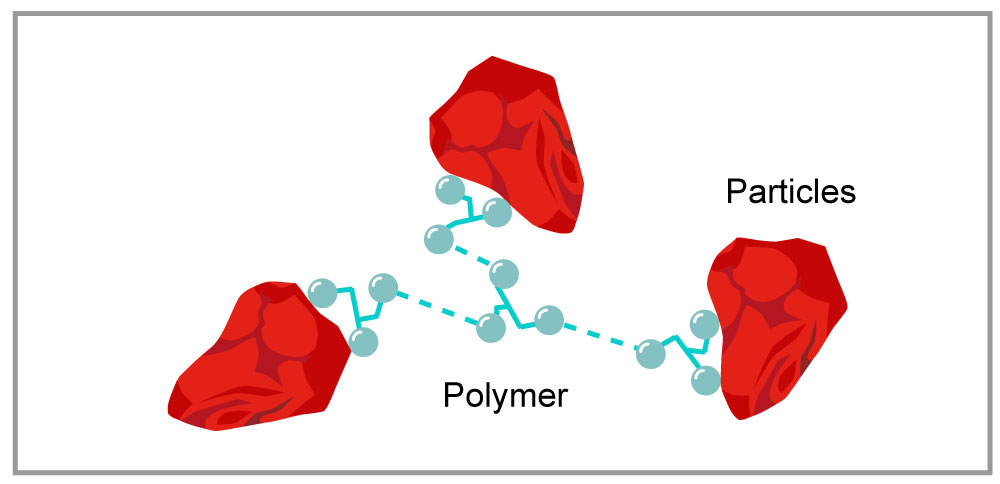

After dispersing to primary particles, flocculant is added to achieve high-speed polishing and high surface quality.