【For firing processing】Fired film/Green sheet

This is the film capable of sintering through firing processing.

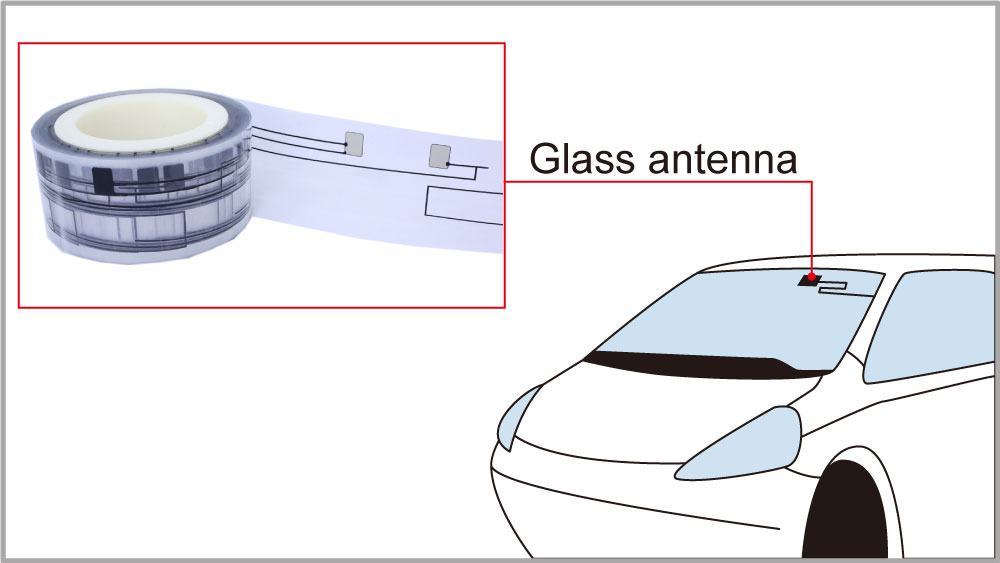

Our fired films are mainly used in automotive antennas for digital TV, enabling us to form robust antennas on glass and other materials. If formed with conductive wire, it can be used as a heater for high temperatures, and it is possible to add a product management code or design that does not peel off to products that require firing processing.

Features

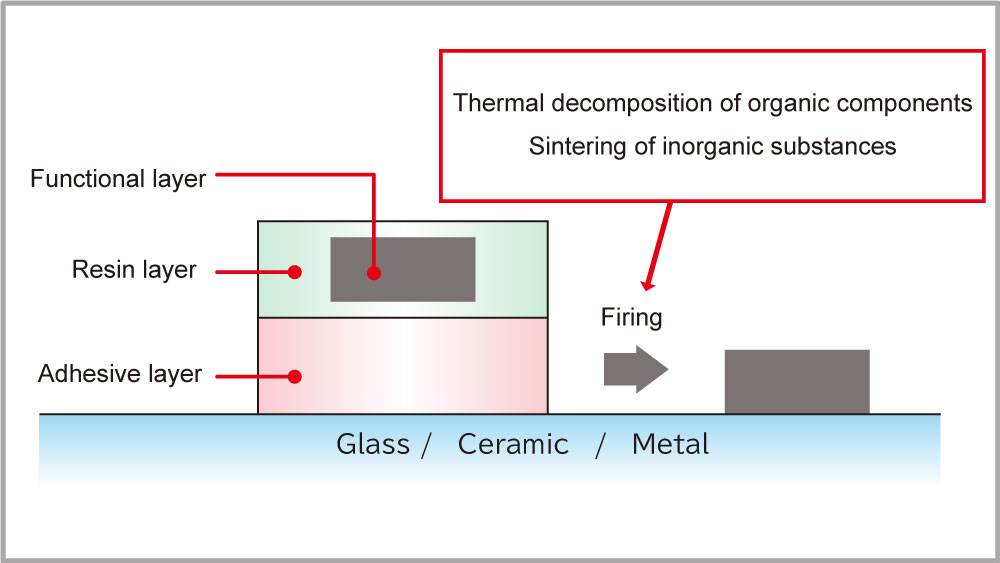

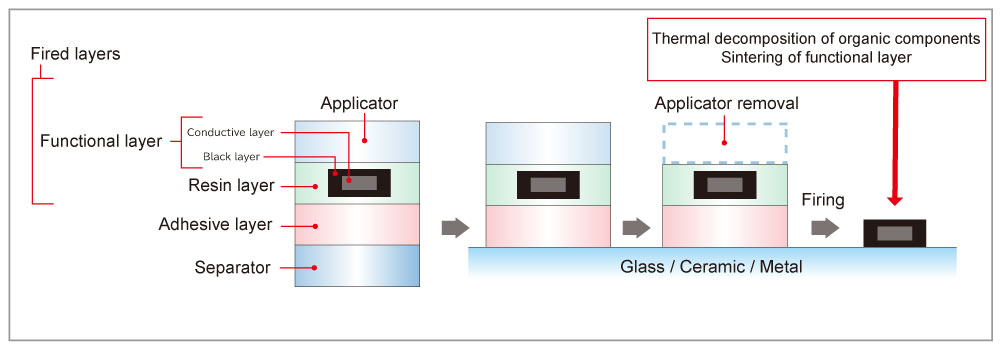

Composition of the fired film

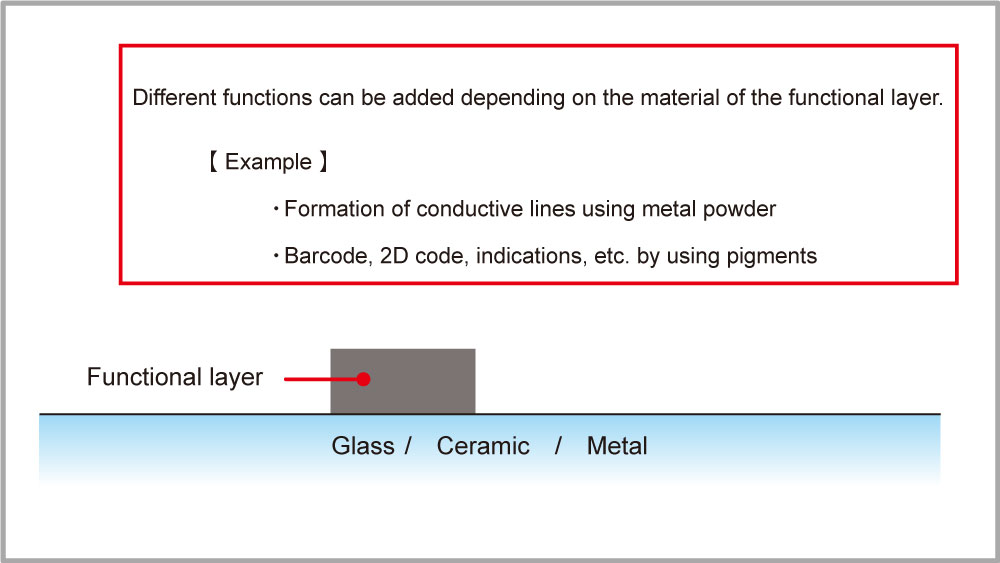

About functional layers

Only inorganic materials in functional layers are sintered on glass, ceramics, or metal by firing.Metals, inorganic pigments, and ceramics can be used for inorganic substances used in functional layers.Different functions can be added depending on the material of the functional layer.

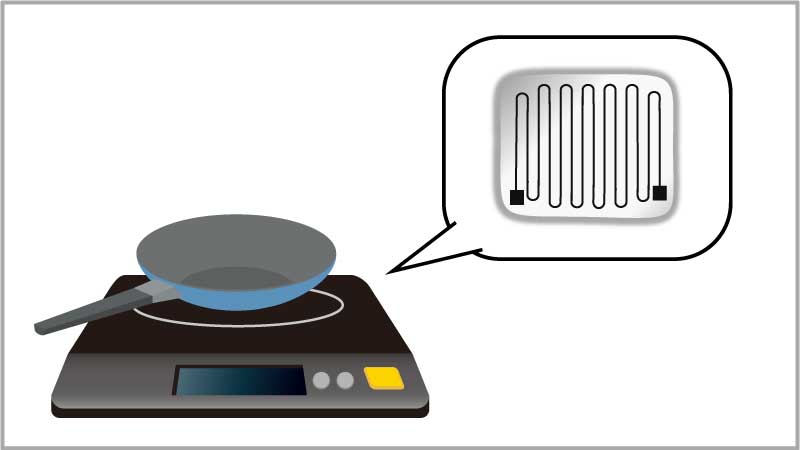

・Conductive materials such as metals

Antennas, heaters for high temperatures, etc.

・Black pigments, etc.

Manufacturing management codes, product labeling, quality indications, cautionary notes, etc.

・Multicolored pigments

Photographic image by ceramic

Regarding the achievements in firing processes

Firing time of adherends can be handled for long or short time.

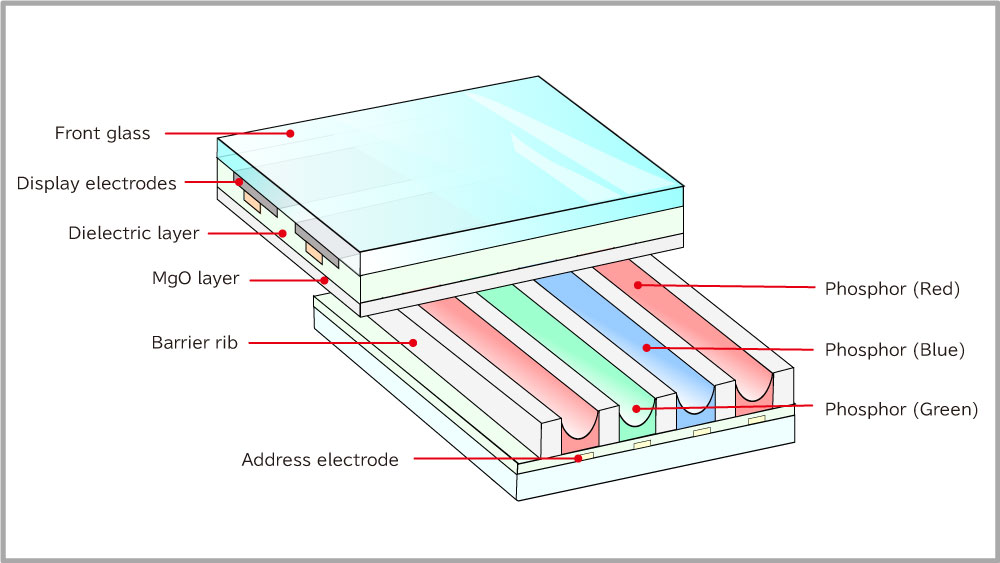

・Achievements of long-time firing

Formation of the barrier ribs of the plasma discharge portion of the plasma display

・Achievements of short-time firing

Antenna for automotive digital TV

The product can withstand intense stresses such as thermal expansion and contraction during heating and cooling, while maintaining its characteristics, quality, and functionality.Depending on the selection of the ceramic material, this material has outstanding durability after firing, and meets extremely strict automotive standards.

Roll screen printing press

Multi-layer possible

Since it is formed by screen printing, it has high positional accuracy and can be printed in multi-layer. For example, an automotive antenna can prevent discoloration of the wiring by overlaying a black ceramic layer, a wiring layer, and a black ceramic layer. In addition, when you want to form a conductive layer through the insulating layer, it is also possible to form a conductive layer on the insulating layer. Thick-film deposition can be formed by high positional accuracy of stacking.

Various applicability

Due to being formed on flexible film, it can also be applied to three-dimensional shapes and curved surfaces. It is also possible to sinter on the flat surface of adherends such as glass, ceramics, and metal.This wiring molding can be done on curved surfaces where printing cannot be performed directly.

Integrated production

Since our fired films are manufactured in an integrated manner, from paint production to commercialization, it is possible to precisely control quality in all manufacturing processes, thus maintaining an excellent level of quality.

Applications for fired films

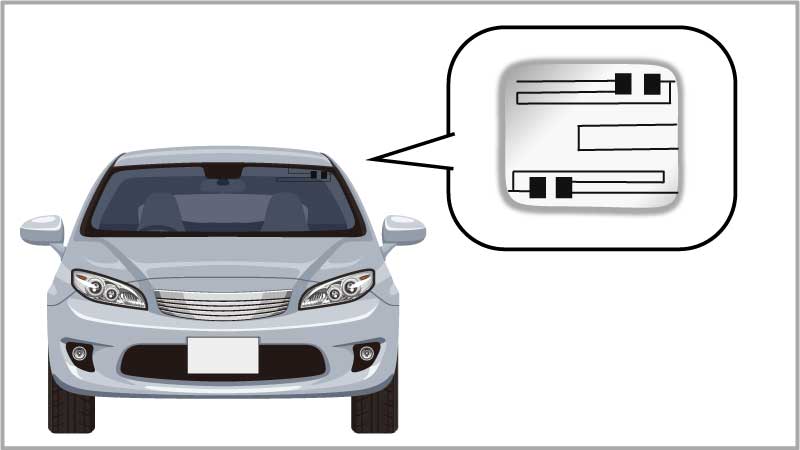

Automotive antenna

Fired films used in automotive digital TV antennas feature a structure where conductive layers are sandwiched between black layers, preventing discoloration of the conductive layers due to chemical reactions.This film enables high-speed firing and multi-layer simultaneous firing according to customer's production line, and is compatible with various patterns of antennas.We can propose dedicated labeling/transfer equipment.

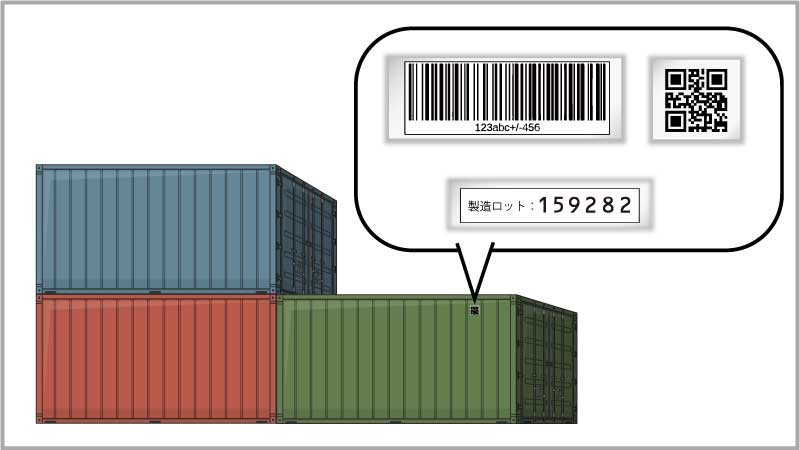

Manufacturing management codes

By sticking and baking two-dimensional identification codes, etc. to products and metal products with processes including firing, such as ceramics, etc., it is possible to give a highly durable code without peeling.This is recommended for those who have problems with labels peeling off due to long-term use.

Design label for glass

This firing-type design label enables high-speed automated application using existing labeling equipment, without requiring water or special treatment. This allows the creation of rich color tones and images, including multi-color and gradient effects that are impossible to achieve through pad printing methods.

How to use fired film by transfer

Form an adhesive layer, a resin layer containing the functional layer, and an applicator on the separator.In use, the separator is removed, and the adhesive layer is transferred onto materials like glass, ceramics, or metals, and then the applicator is removed. By firing at temperatures exceeding 500°C, the organic components of the functional layer, resin layer, and adhesive layer are thermally decomposed, leaving only the functional layer composed of inorganic substances sintered onto the substrate.

[We offer manufacturing outsourcing for wiring formation technology.]

If you have any manufacturing issues, please feel free to contact us.